TechSheet

| Number of gears | 6 + N | |

|---|---|---|

| Overall gear ratio | 396 % | |

|

Dropout variants |

135 mm x 10 | |

| 142 mm x 12 | ||

| 148 mm x 12 | ||

| Brake disc size | 180 mm | |

| 203 mm | ||

| Chainline | 54,7 mm | |

| Sprocket / belt mount | 9-Spline | |

| Gear | Gear Ratio |

Development (distance covered)

44:15 Primärübersetzung, 29″ Rad |

| 1st Gear | 3,15 | 2,21 |

| 2nd Gear | 2,34 | 2,97 |

| 3rd Gear | 1,74 | 3,99 |

| 4th Gear | 1,47 | 4,75 |

| 5th Gear | 1,00 | 6,96 |

| 6th Gear | 0,80 | 8,74 |

| Maximales Drehmoment |

No Limit A safety clutch protects the gearbox |

|

| Oil change interval | First change after 1000 km or one year | |

| Subsequent changes after 5000 km or once per year | ||

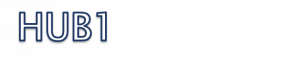

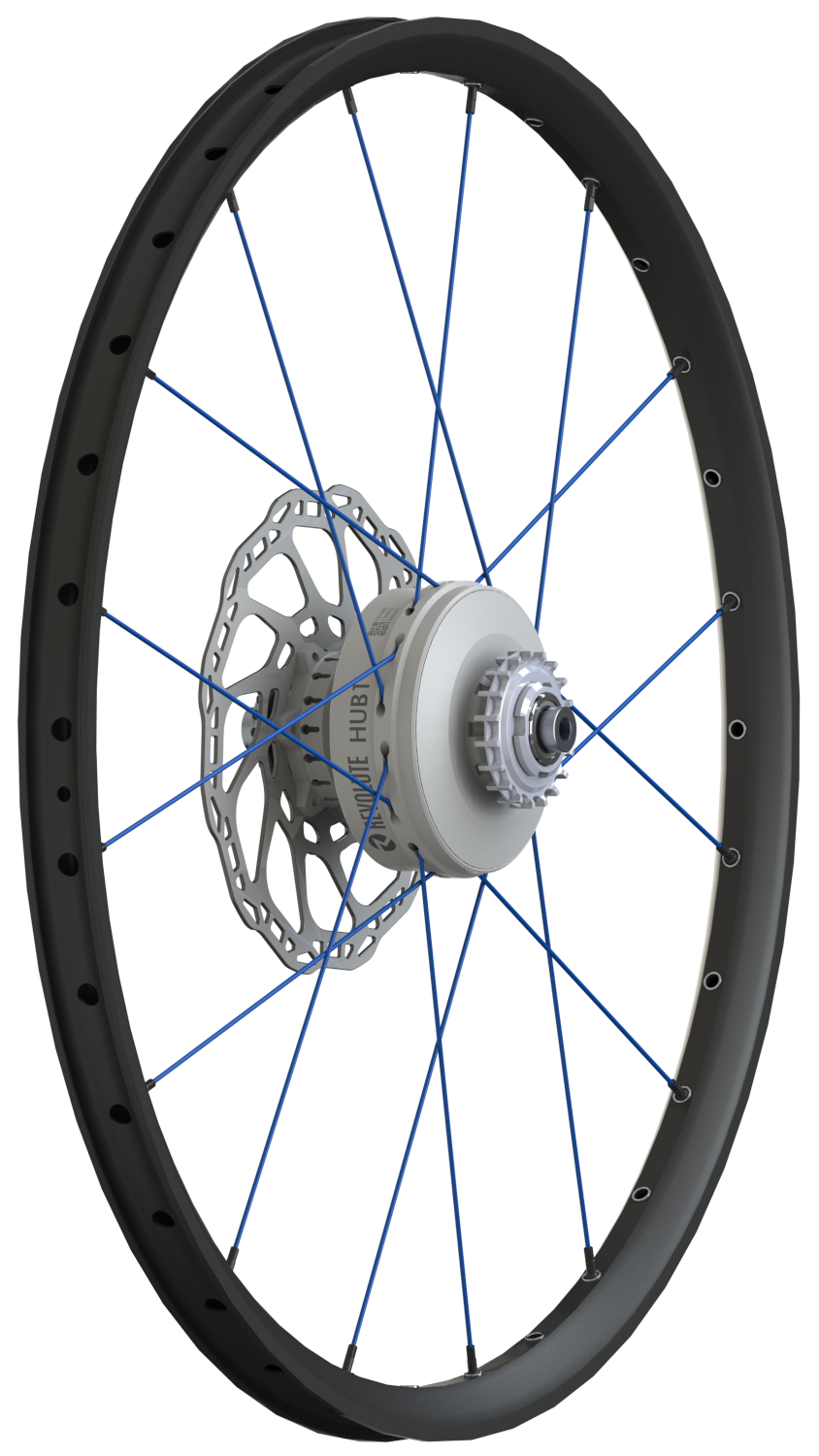

| Number of spokes | 32 | |

| Type of spokes | Straightpull | |

| Rim sizes | 20″ - 29″ | |

| E-Bike requirements | Free wheel at the crank/ motor | |

| Weight | < 2 kg | |

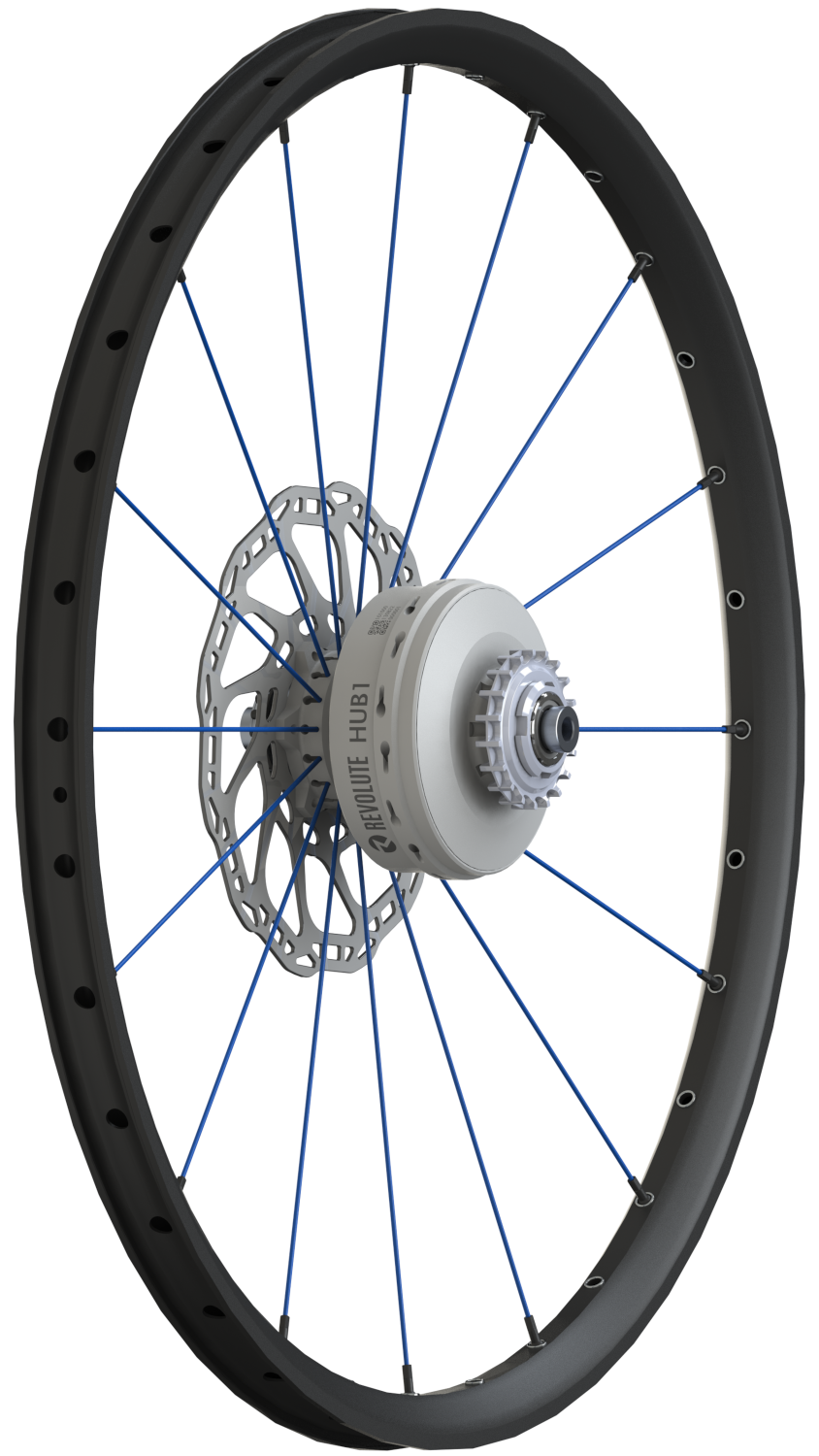

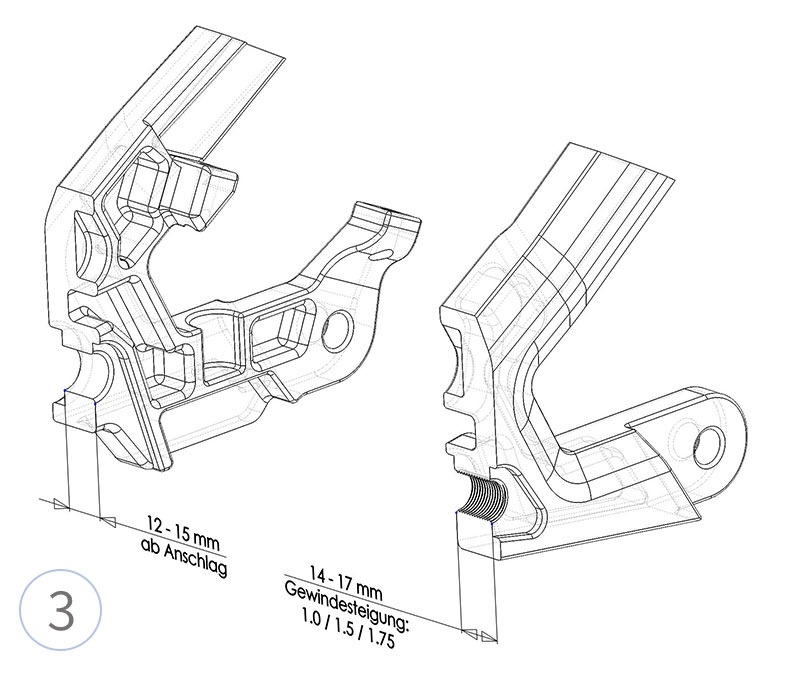

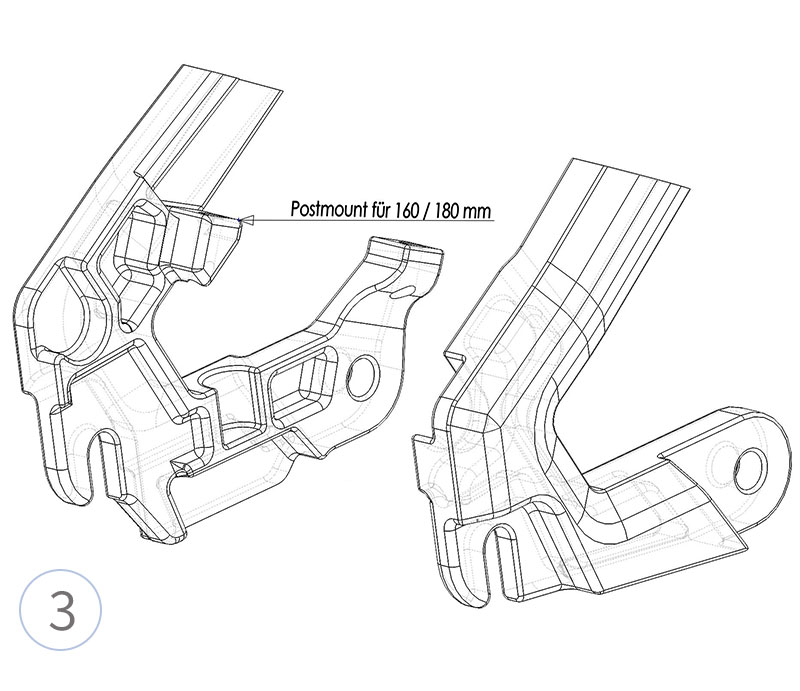

Compatibility Thru Axle System

There must be a straight mounting surface for the adapter on the outside of the frame with a minimum diameter of 20 mm.

The frame width between the dropouts needs to be 142 or 148 mm. Postmount points suitable for 160 mm or 180 mm brake disc are necessary.

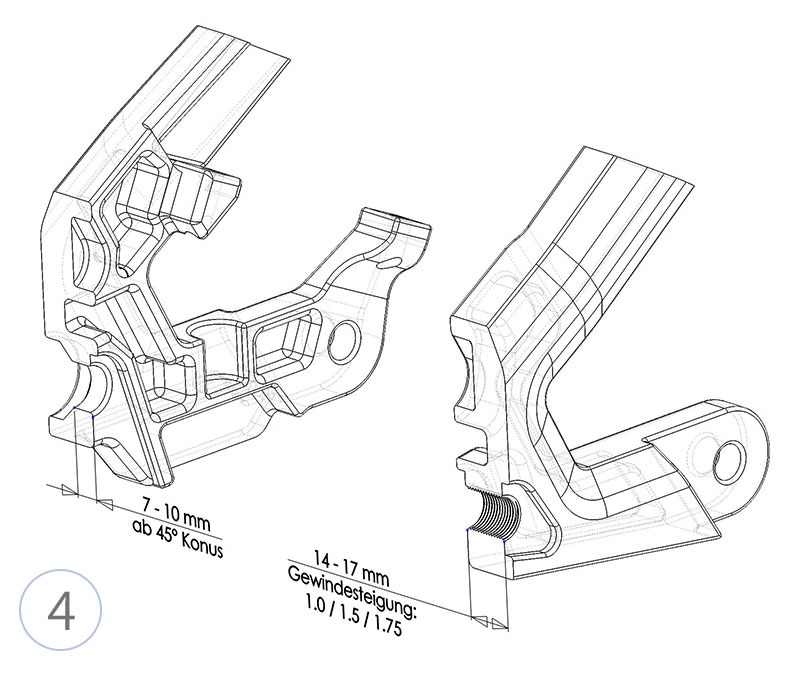

If there is a straight stop at the left dropout, the frame width must be between 12 and 15 mm. The frame width on the right side must be 14 - 17 mm and there must be a M12 thread with a pitch of 1.0, 1.5 or 1.75.

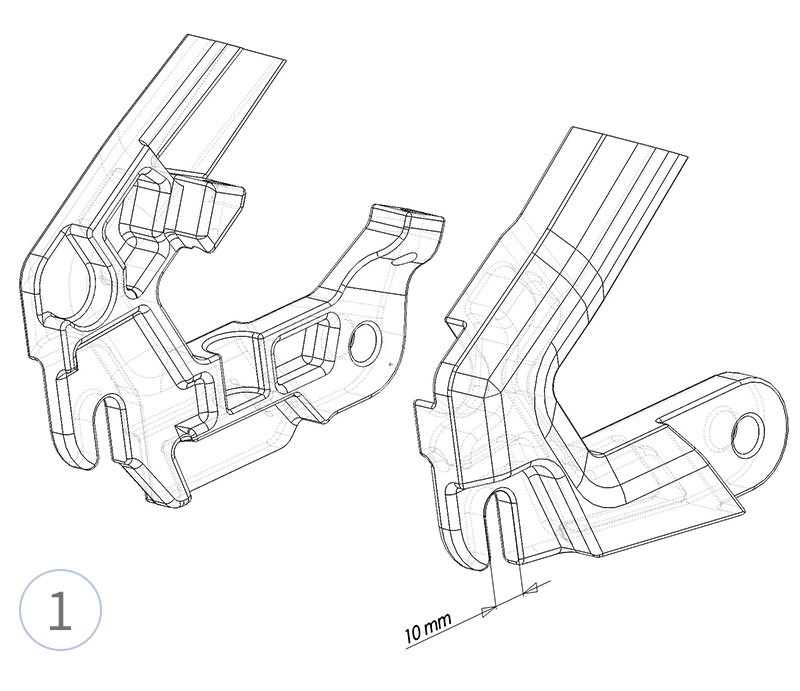

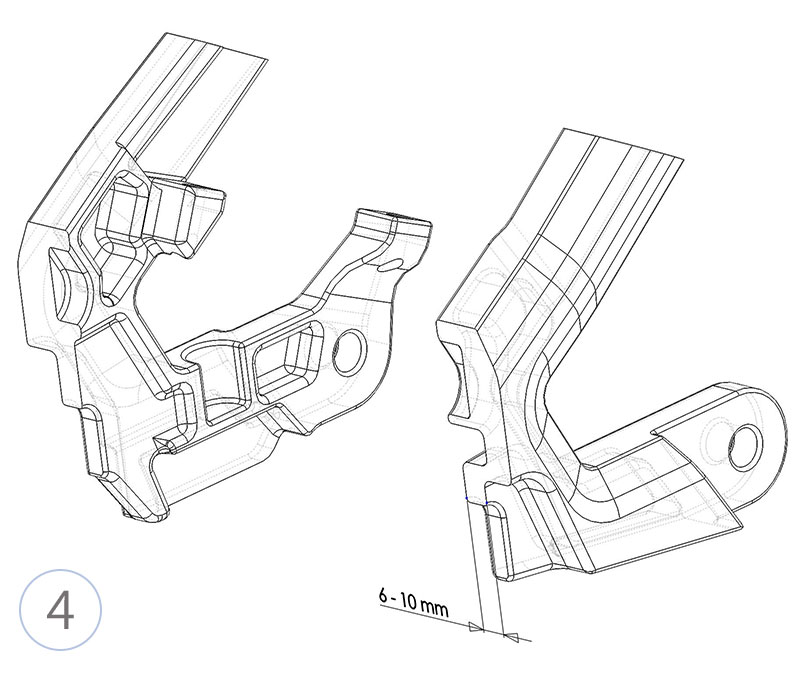

If there is a 45° cone at the left dropout, the shown dimension must be between 7 and 10 mm.

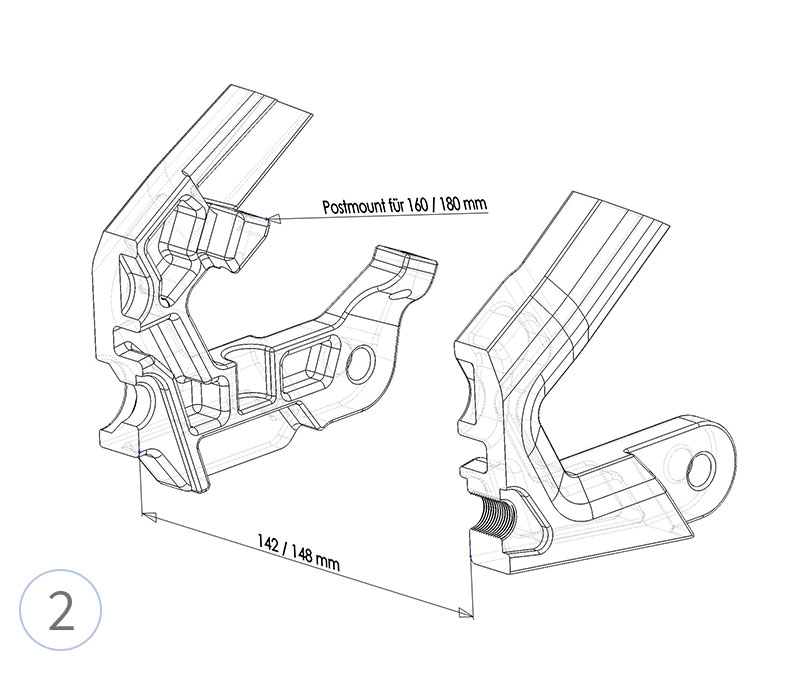

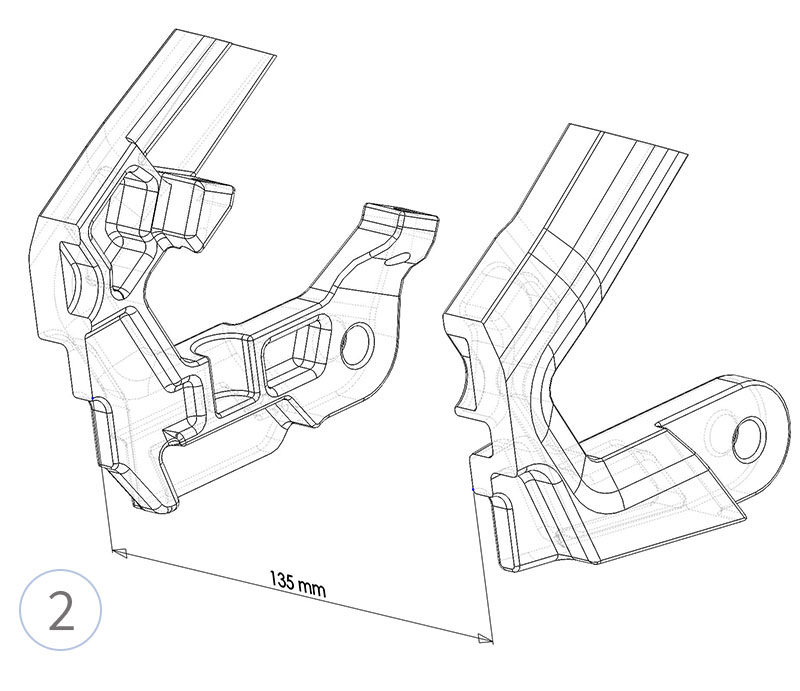

Compatibility Vertical Dropouts

The hooking area for the axis must be slightly more than 10 mm in diameter or width.

The frame width between the dropouts needs to be approx. 135 mm.

There must be postmount screw-on points for a 160 mm or a 180 mm brake disc.

The frame thickness must be between 6 mm and 10 mm at the axle mounting surface.

FAQ

Allgemeines

Do you still have questions or just want to know a bit more? Then take a look at the following questions and answers:

Revolute provides documentation for installation. However, a certain level of expertise is required to install the hub in such a way that safe operation can be guaranteed. For motivated retrofitters with less experience in the field of two-wheel mechanics, we offer a spoking service, which is carried out by our partner SES - Sandmann Ersatzteil Service. We do not carry out the final installation of the hub itself. However, installation instructions are supplied with every hub, so that the retrofit can also be carried out by yourself - in a reasonable amount of time and possibly with the support of your local bike dealer.

You can book the spoking of the hub when ordering for a reasonable surcharge. Spoking is carried out by our reliable and competent partner SES – Sandmann Ersatzteil Service.

Spoking is described in detail in the manual supplied with the hub.

Oil lubrication reduces friction. This results in better efficiency. In addition, oil can be changed in the event of ageing or moisture absorption, which ensures a long service life for the hub.

No, there is only a grip shift.

The HUB1 is 'Made in Germany'. This means that all components - with the exception of some standard parts - are manufactured in Germany. Quality control and assembly take place exclusively at Revolute in Germany.

The HUB1 has a safety clutch. At approx. 250 Nm at the crank (primary ratio 44:15), the clutch briefly slips and thus automatically limits the torque. If the torque decreases again, the full force is transmitted again. This effectively protects the system from damage due to overload.

Funktionen

When riding an e-bike, there is significantly less gear shifting due to the motor assistance than when riding a sporty road bike, for example, so 6 gears are sufficient.

For example, you can shift gears on hills and do not lose speed if you shift too late. You can also shift gears when the motor is still assisting. There are no shifting errors or misfires.

The hill start assist is noticeable by the fact that you cannot roll backwards in forward gears 1-6. The concept is similar to that of modern cars, but is implemented mechanically and not electrically. If you want to maneuver or push backwards, you switch the twist grip to the "N" position (neutral gear) and can easily move the wheel - however, there is no power transmission from the pedals in this position.

To override the hill start assist and be able to push the wheel backwards.

Compatibility

Yes, it is even optimized for use in e-bikes.

As we use the freewheel of the electric motors to implement a hill start aid or a roll-back stop, the current version of the hub is only intended for use in e-bikes.

No, so far there are only our own brake disks. These have been developed with a well-known German manufacturer and can be used for all standard brake systems. The bolt circle differs from previously available brake discs.

Yes, if it has 32 spoke holes.

The HUB1 can be installed in all standard bikes with thru axles, although the thru axle is replaced by a number of adapters. The HUB1 does not have a through hole through which a thru axle can be inserted. You can find the necessary data in the compatibility requirements and on the Techsheet.

The HUB1 can be installed in all standard bikes with O.L.D., but the quick-release skewers are replaced by a few adapters. The necessary data can be found on our homepage.

There are currently 135 mm, 142 mm and 148 mm. 150 mm is currently being tested

The sprocket has a Shimano 9-spline mount and can therefore also be replaced.

Yes, the HUB1 is compatible with standard pulleys that fit the existing Shimano 9-spline mount and are no wider than 5 mm.

Yes, we recommend using a chain or belt tensioner for the best riding experience and longevity and making the sprocket wrap as large as possible. The SB One chain tensioner is particularly suitable.

Currently 2.0 mm straight pull spokes. In the future, 2.3 mm will also be possible.

1200 N or the maximum spoke tension permitted by the rim used.

The HUB1 was tested in various wheel sizes (20“, 26”, 27.5“ and 28”) in accordance with DIN EN 15194:2018-11 and also underwent dynamic brake, roller and freewheel tests. If you would like to view the test protocols, please contact us.

DIN EN 15194:2018-11: This European standard describes the requirements for electrically assisted bicycles with a maximum continuous rated power of 0.25 kW. The electric motor switches off as soon as the bicycle reaches a speed of 25 km/h.

REVOLUTE expressly approves the HUB1 only for use in unmodified pedelecs in accordance with DIN EN 15194:2018-11. If the HUB1 is operated in e-bikes that do not comply with this standard, the guarantee/warranty becomes void.

The HUB1 can be installed in more powerful e-bikes at your own risk and without warranty/guarantee claims. The system is protected against overload by a safety slipping clutch. Many customers are already using the HUB1 in high-performance e-bikes.

No, only the original HUB1 oil will work, as this is the only oil that can ensure problem-free operation. Other oils can damage the HUB1 due to various additives. The HUB1 oil has been specially developed for the requirements of the HUB1 and its riders.