THE FUTURE OF GEAR HUB SYSTEMS

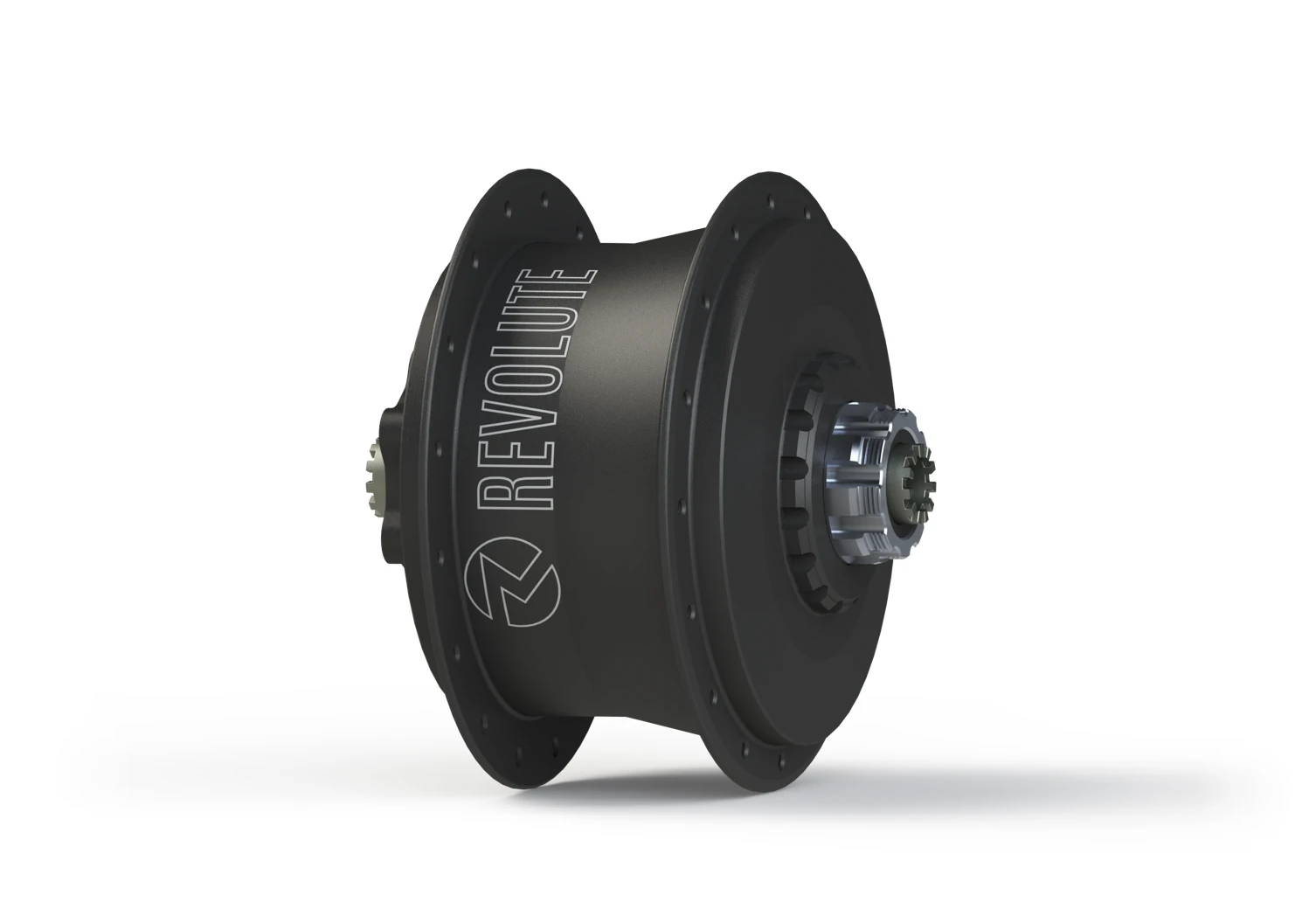

HUB A8

THE FUTURE OF GEAR HUB SYSTEMS

KEY FACTS

- Intelligent automatic transmission with 8 gears

- Suitable for e-bikes and bio-bikes

- 419% total gear ratio and optimum gear steps

- One of the lightest automatic gear hubs

- No cables, no Bowden cables, no charging

- Thru axle compatible

- No complicated adapter solutions

- Compatible with 6-bolt brake discs

- Maintenance-free with lifetime lubrication

- Belt compatible

- Easy service

FUTURE OF GEAR HUBS

AUTOMATIC

The intelligent automatic takes your driving experience to a whole new level!

The new HUB A8 shifts gears fully automatically and selects the perfect gear based on various sensor values. Simply select your desired cadence in the REVOLUTE app and the HUB A8's intelligent electronics will take care of everything else. Sporty riders can optionally use the REVOLUTE wireless trigger. Choose between automatic, manual or individual modes. In individual mode, a wide range of parameters and features can be customized to suit your personal preferences. The system can therefore work completely independently of the electric drive.

WIRELESS

The HUB A8 shifts gears completely electronically, NO cables and NO charging required.

The electronic shifting does not require an external power supply, e.g. from the e-bike battery. There is also no need to charge the internal battery. The HUB A8 utilizes a tiny part of the kinetic energy of the hub. Thanks to an intelligent control system and various sensors, the hub can decide independently when the optimum time is to charge the internal battery, for example when braking.

This means that no cables or connections are required. The initial configuration after purchase is carried out via the REVOLUTE app. This can then also be used to set the desired cadence.

PLUG AND PLAY

Installing a hub gear has never been so easy — the HUB A8 is ready to use in no time at all!

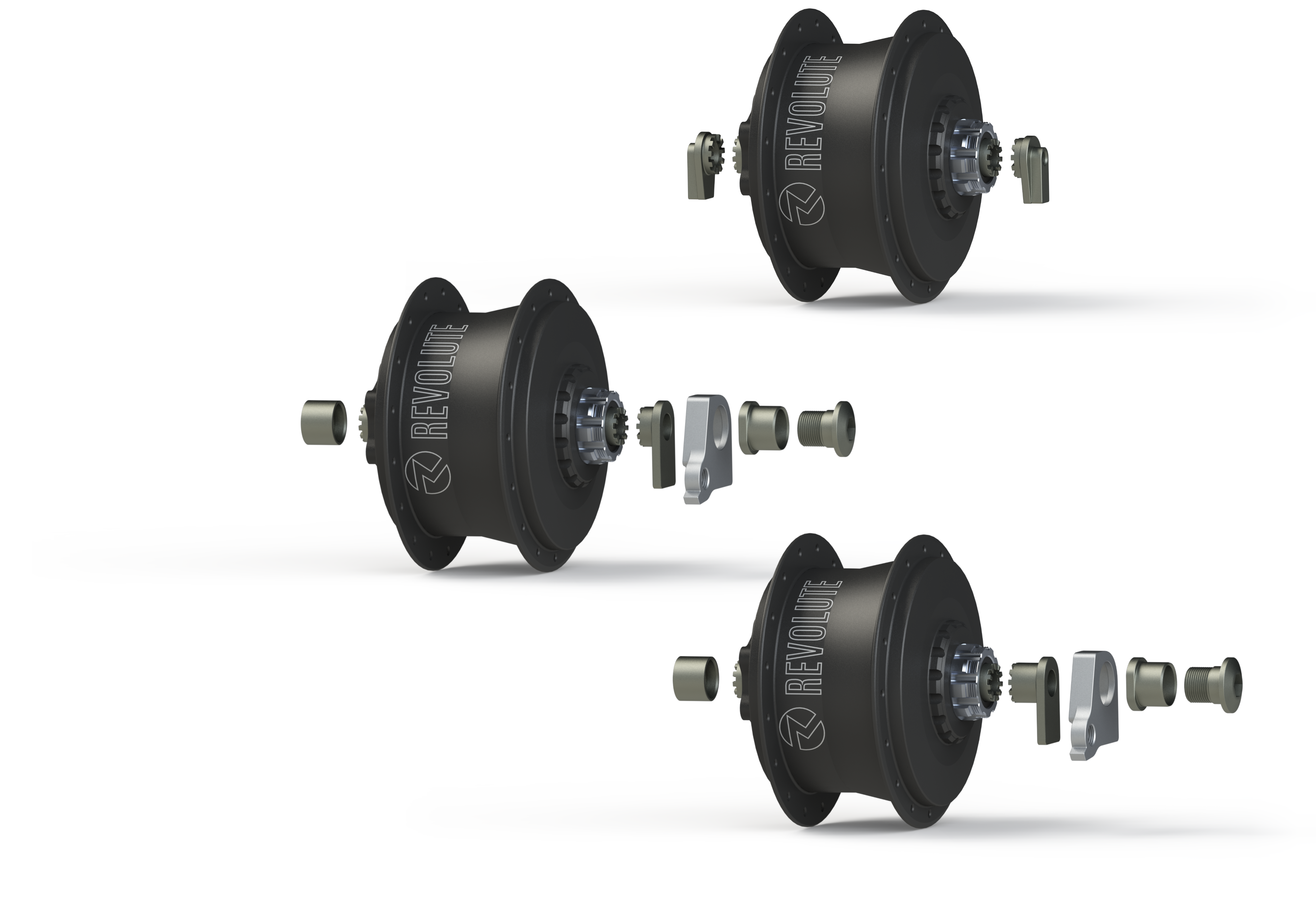

Whether you have a quick-release axle or UDH standard, installing the HUB A8 is extremely quick and easy. For bikes with a 12 mm thru-axle and the UDH standard, simply replace the original UDH derailleur hanger with an adapter from REVOLUTE and continue to use the original thru-axle. Installation in frames with a 135 mm frame width and a quick- release axle is even easier; here, only the wheel needs to be replaced. Continue to use the original quick-release axle here too.

No cables or Bowden cables need to be installed! You also don't have to install a complicated adapter solution on the brake to support the reaction torque!

Configure the HUB A8 in minutes with the REVOLUTE app and you can start your first tour

MAINTENANCE-FREE

You don't have to worry about anything except riding and having fun.

The HUB A8 is supplied with a lifetime lubrication. You don't have to worry about anything else. All electronic components are also installed inside the housing and protected from harmful environmental influences. The technical design also eliminates the need for any adjustment or calibration work.

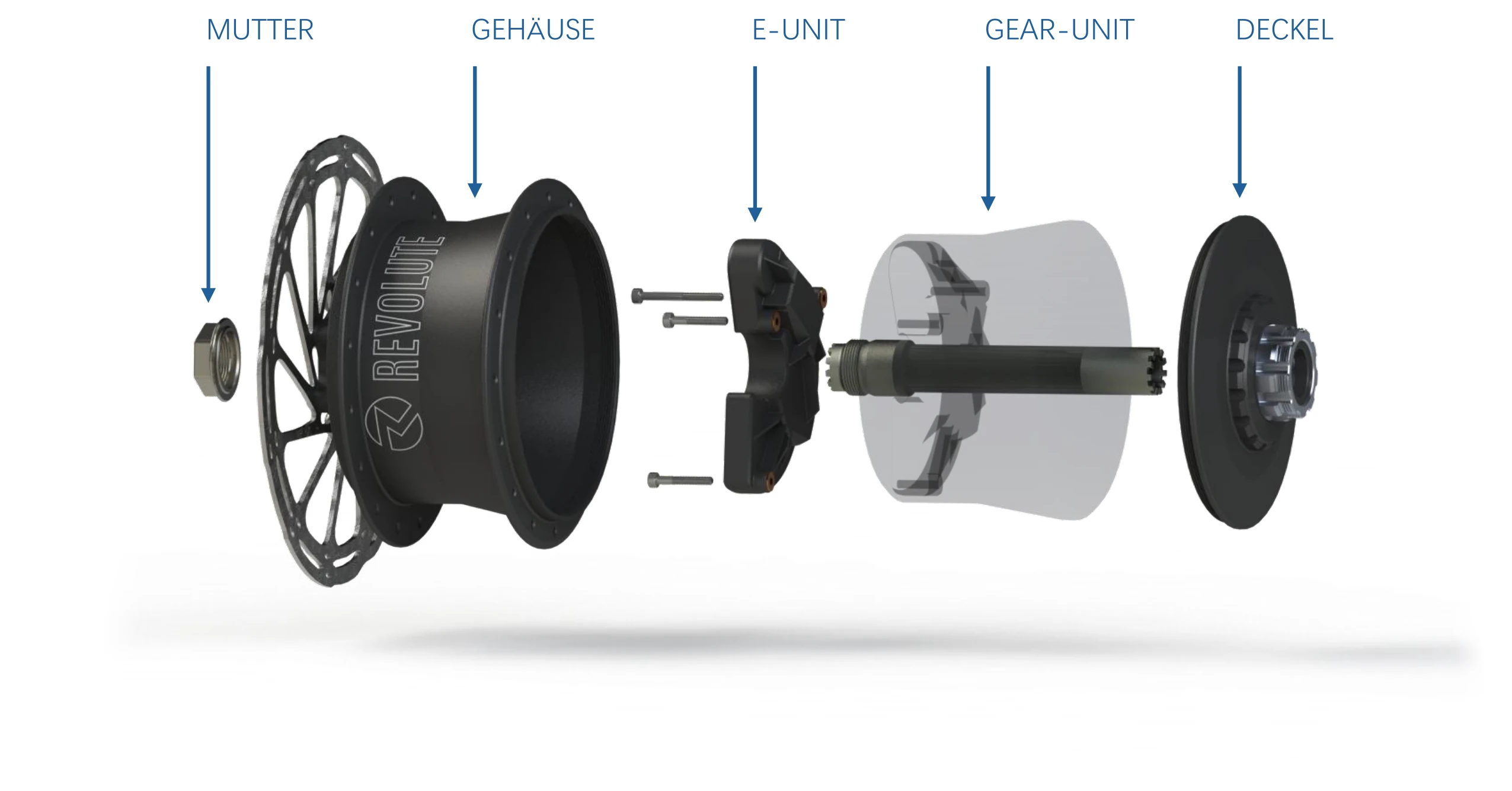

Service

The HUB A8 is specially designed for easy, quick, and inexpensive servicing. Thanks to its clever design, servicing can be completed in just a few simple steps. The relevant components of the gearbox can be replaced directly at the dealer or service partner.

ADVANTAGES

- Low service costs: No need to send the entire wheel for servicing.

- Highest customer satisfaction:End customers appreciate simple, comprehensible solutions, which increases brand loyalty and trust.

- Modular concept: E-UNIT and GEAR-UNIT can be replaced separately in a short time.

- Fast service: If the dealer has replacement parts in stock, the customer can continue riding on the same day

- Ecological: In case of service, it is not necessary to replace the entire gearbox.

PROCEDURE

- Remove pinion or pulley

- Open cover with COVER-TOOL

- Open nut with socket wrench

- Remove GEAR-UNIT and E-UNIT

- Replace E-UNIT or GEAR-UNIT

- Reassemble in reverse order

Specifications

specifications

| Number of gears | 8 |

| Gear Shift | Automatic (optional manual via wireless trigger) |

| Overall gear ratio | 419 % |

| Maximum input torque | 120 Nm |

| Use in e-bikes | Yes, according to DIN EN 15194:2018-11 |

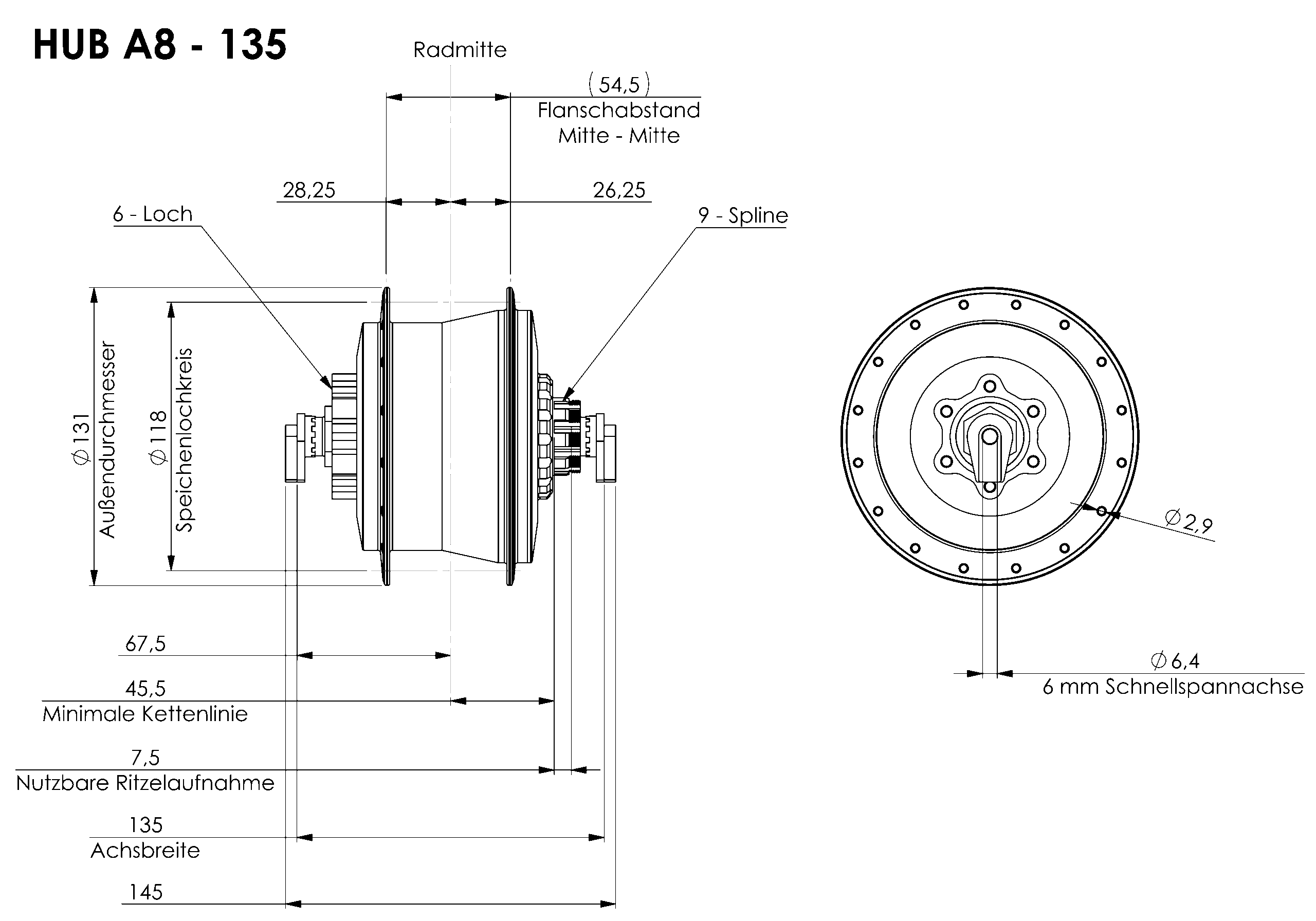

| Compatible frame widths | 135 mm O.L.D. |

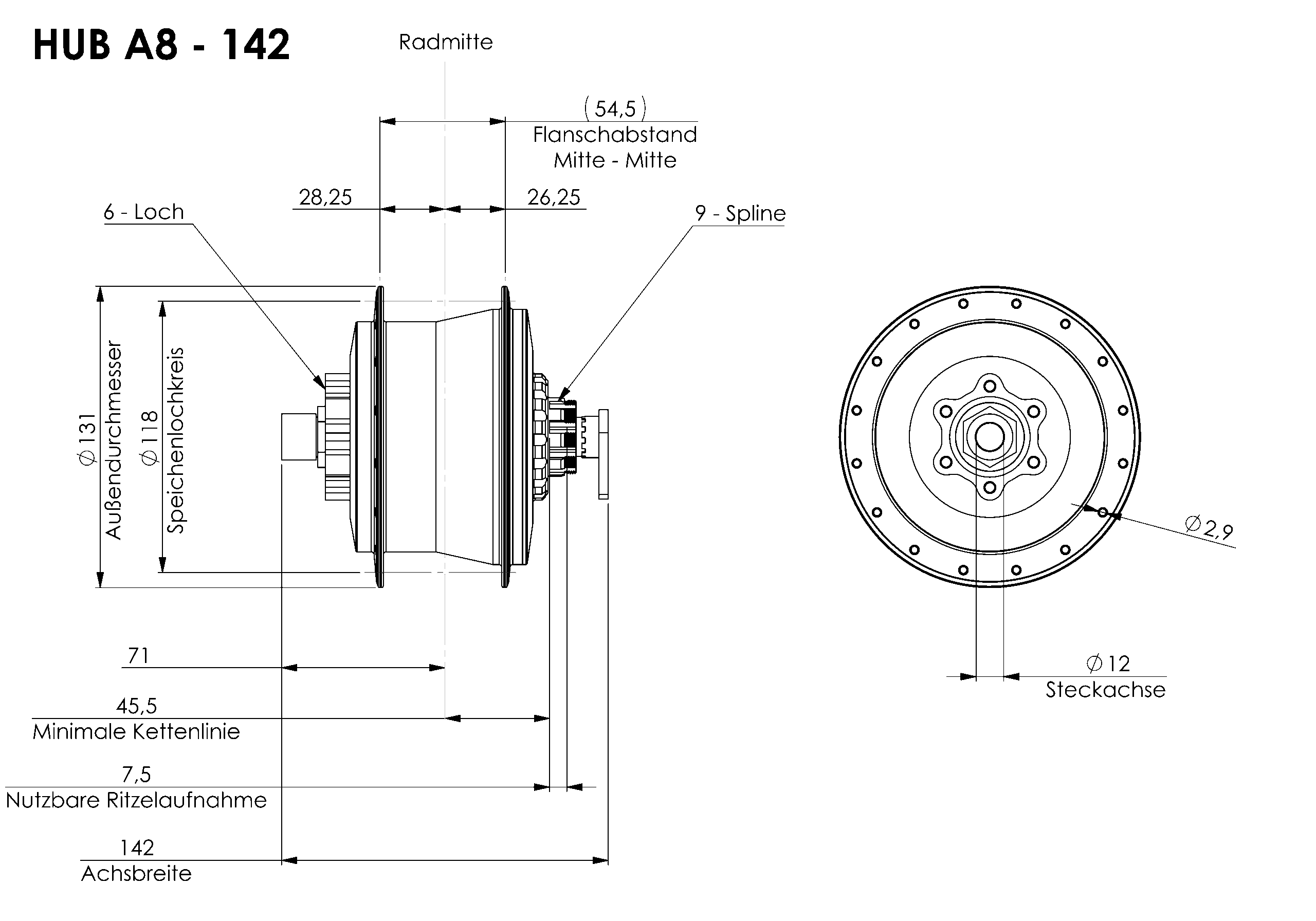

| 142 mm with UDH | |

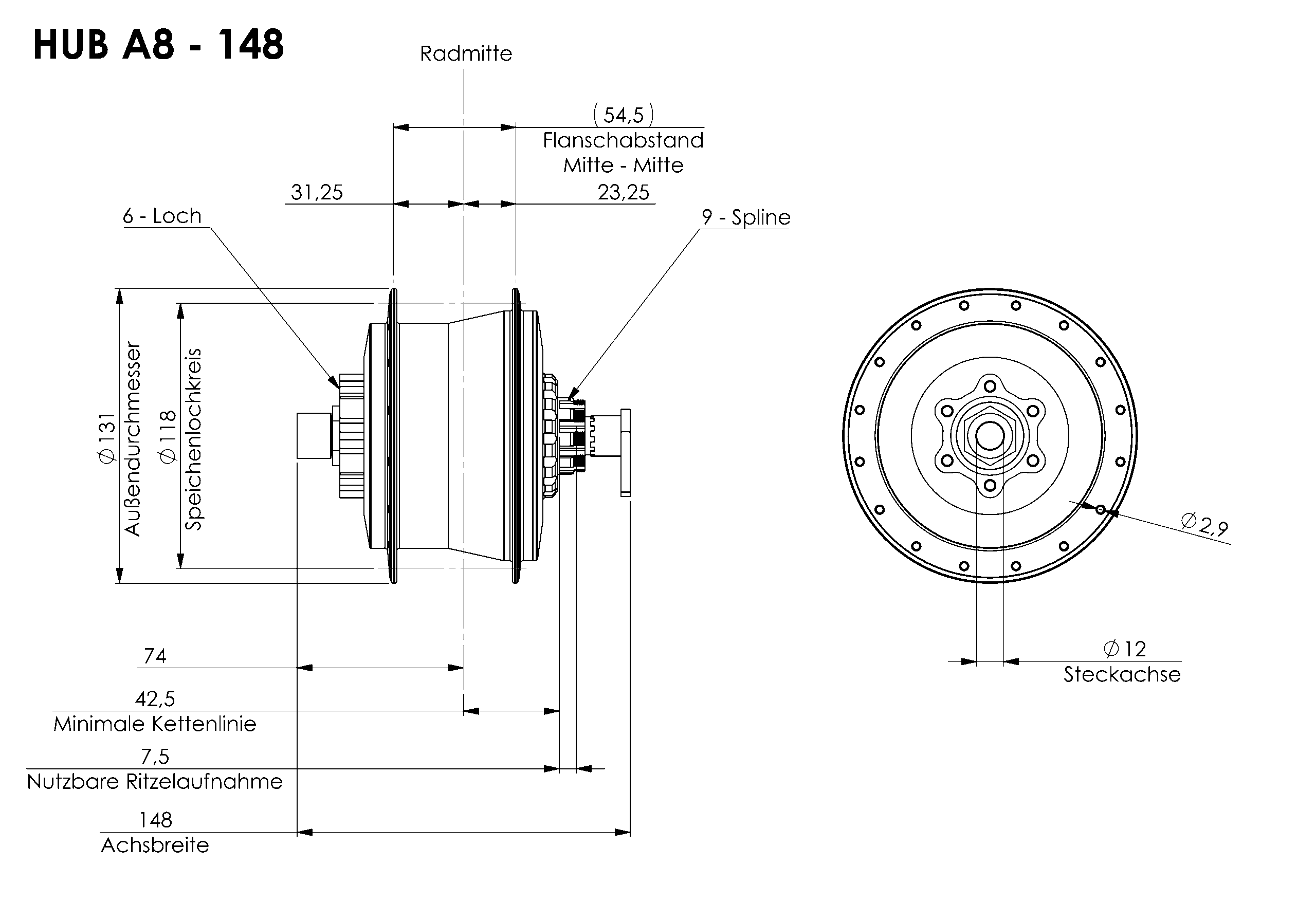

| 148 mm with UDH | |

| Axle | Original thru axle / quick release axle |

| Torque Support | using 135 mm adapter |

| using 142/148 mm UDH adapter | |

| Number of Spokes | 32 or 36 |

| Spoke flange distance | 54,5 mm |

| Spoke hole diameter | 2,9 mm |

| Spoke flange width | 3,2 mm |

| Hole circle diameter of the spokes | 118 mm |

| Rim sizes | 20″ and larger |

| brake discs | All 6-hole brake discs |

| Brake disc bolt length | 10 mm |

| Torque for brake disc screws | Manufacturer's specifications, but max. 6.2 Nm |

| Brake disc sizes | 160 mm or larger |

| Primary transmission ratio | 2 or greater |

| Pinion Mount | 9-Spline |

| Chainline | 135 mm: 45.5 mm (45.5–51 mm with spacer) |

| 142 mm: 45.5 mm (45.5–51 mm with spacers) | |

| 148 mm: 42.5 mm (42.5–48 mm with spacers) | |

| Temperature Range | −20 °C to +50 °C |

| Lubrication | Grease (lifetime filling) |

| Wartung | Not necessary |

| Weight | ~1.8 kg including integrated electrical circuitry |

| Color | Matte black |

TRANSMISSION

| Gear | Translation | Gear Steps | |

|---|---|---|---|

| 1 | 2,22 | 1,21 | |

| 2 | 1,84 | 1,20 | |

| 3 | 1,54 | 1,20 | |

| 4 | 1,29 | 1,21 | |

| 5 | 1,07 | 1,22 | |

| 6 | 0,87 | 1,25 | |

| 7 | 0,70 | 1,32 | |

| 8 | 0,53 | ||

Gear Steps

Development (distance covered)

Exemplary development

Adapter

ADAPTER

O.L.D.

UDH

UDH

O.L.D.

UDH

UDH

Dimensions